Diamond Slurries / Diamond Powders / Pad For Lapping & Polishing / Diamond Tools

Applications (Materials):

Way choose Qual Diamond Slurries

• High purity and precise narrower particles size distribution provide a solution for high quality and high purity processing requirements

• Excellent stability and lubrication conduct excellent polishing performance

• Outstanding viscosity thixotropy make processing easily

• Ensure consistency of multiple cutting edges and polishing results even with the irregular shapes of a single crystal structure or the hardest diamond nano/microparticles

• Perfectly even finishes with all types of machines

•Unique slurry formulation provides best polishing pad surface wetting and adhesion rate, higher polishing efficiency, and less slurry consumption

• Excellent for distributing diamond easily and uniformly over the cloth or platen surface

• From raw materials to finished products are all Made by renewables bio-based and environmentally-friendly materials

• Qual Diamond's innovative formulation greatly improves the efficiency of cleanup, 99% slurry can be easily cleaned from the surface of processing material and machine within 10-15 minutes, perfectly protecting the material and machine

• Our slurry can be stably Sustained in –20°C to 50°C environment

• It is the ideal slurry for automatic polishers and various applications

Slurry - Available Sizes and Types:

Hydroqual Standard Monocrystalline (HSM) Diamond Slurry - Qual Diamond’s HPHT Monocrystalline Diamonds are manufactured by water -base hydroquals and suspending nano to micro size diamond powder with unique surface treatment. Which is widely used for advanced ceramic, optics, and semiconductor fields.

Hydroqual Advanced Monocrystalline (HAM) Diamond Slurry - HAM is Qual Diamond HPHT Monocrystalline advanced formulas diamond slurries, are manufactured by homogeneously dispersing and suspending nano or micro grade diamond particles into formulated glycol-soluble Hydroquals, which allows more stability in all hostile environments and provide superior polishing performance.

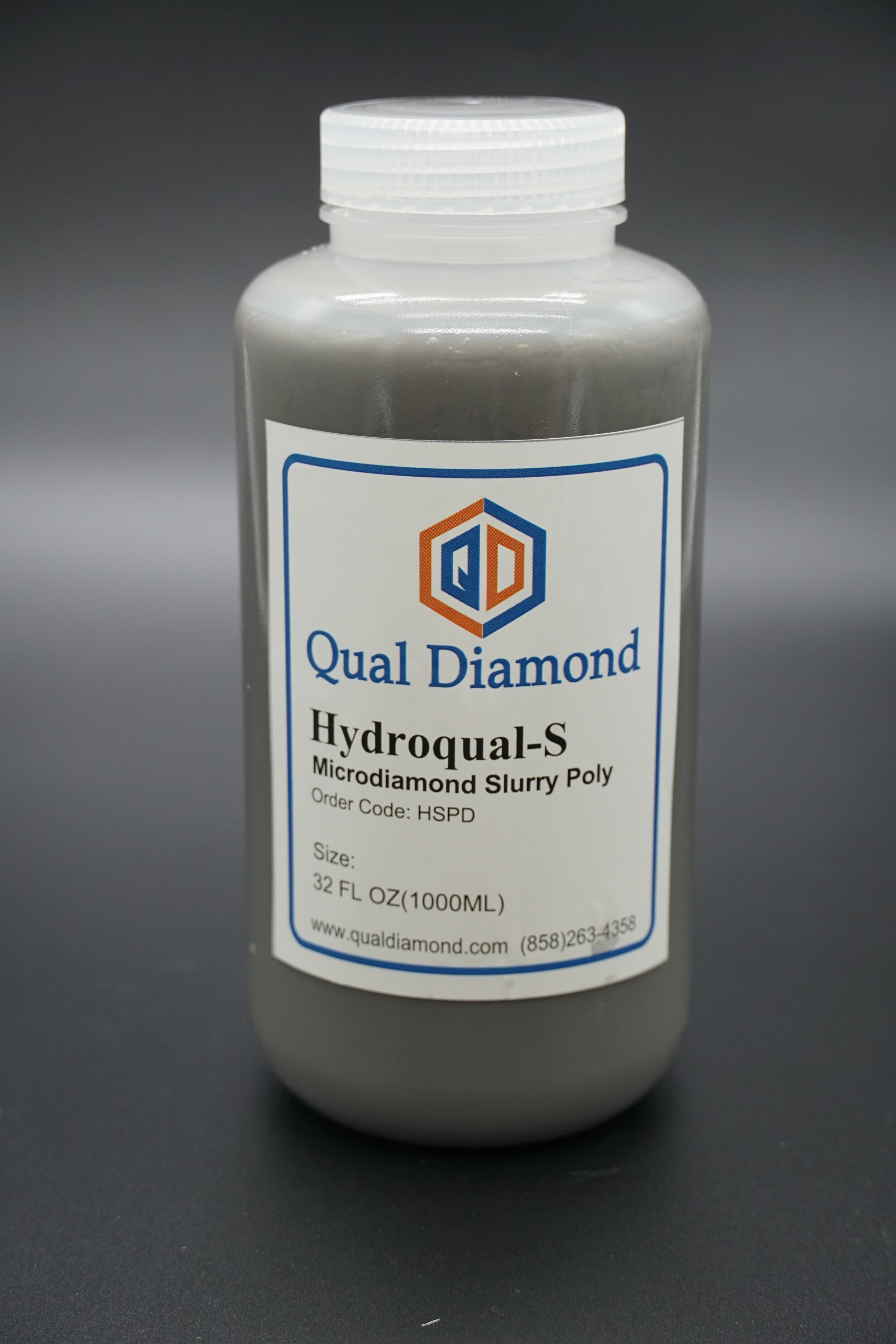

Hydroqual Standard Polycrystalline (HSPD) Diamond Slurry - are manufactured by homogeneously dispersing and suspending detonated polycrystalline nano or micro grade diamond particles into standard formulated water-base Hydroquals, Widely used for lapping and precision polishing of materials such as silicon chips, optical devices, metallic works, etc.

Hydroqual Advanced Polycrystalline (HAPD) Diamond Slurry - are manufactured by homogeneously dispersing and suspending detonated polycrystalline nano or micro grade diamond particles into advanced formulated glycol-soluble Hydroquals, Widely used for lapping and precision polishing of materials such as silicon chips, optical devices, metallic works, etc. efficiently Eliminates subsurface deformation.

Hydroqual Standard Polycrystalline (HSPH) Diamond Slurry - manufactured from HPHT polycrystalline diamond particles, which homogeneously dispensing and suspending in unique formula water-base hydroquals. Perfectly fulfill uniform surface finish. Multiple self-sharpening micro-cutting edges providing faster material removal rates are widely adopted for lapping and polishing by optics, metallic works, semiconductors, etc. industries.

Hydroqual Advanced Polycrystalline (HAPH) Diamond Slurry - manufactured from HPHT polycrystalline diamond particles and advanced Glycol-soluble hydroquals which offer more narrow grits size distribution and homogeneous dispersion. Perfectly fulfill uniform surface finish. Self-sharpening Multiple micro-cutting edges providing faster material removal rates are widely adopted for lapping and polishing by optics, metallic works, semiconductor, etc. industries